Catch Defects Early. Keep Production Moving.

AI-powered Visual Inspection that detects defects in real time, prevents downtime, and keeps your production running at full speed.

One Standard: Flawless

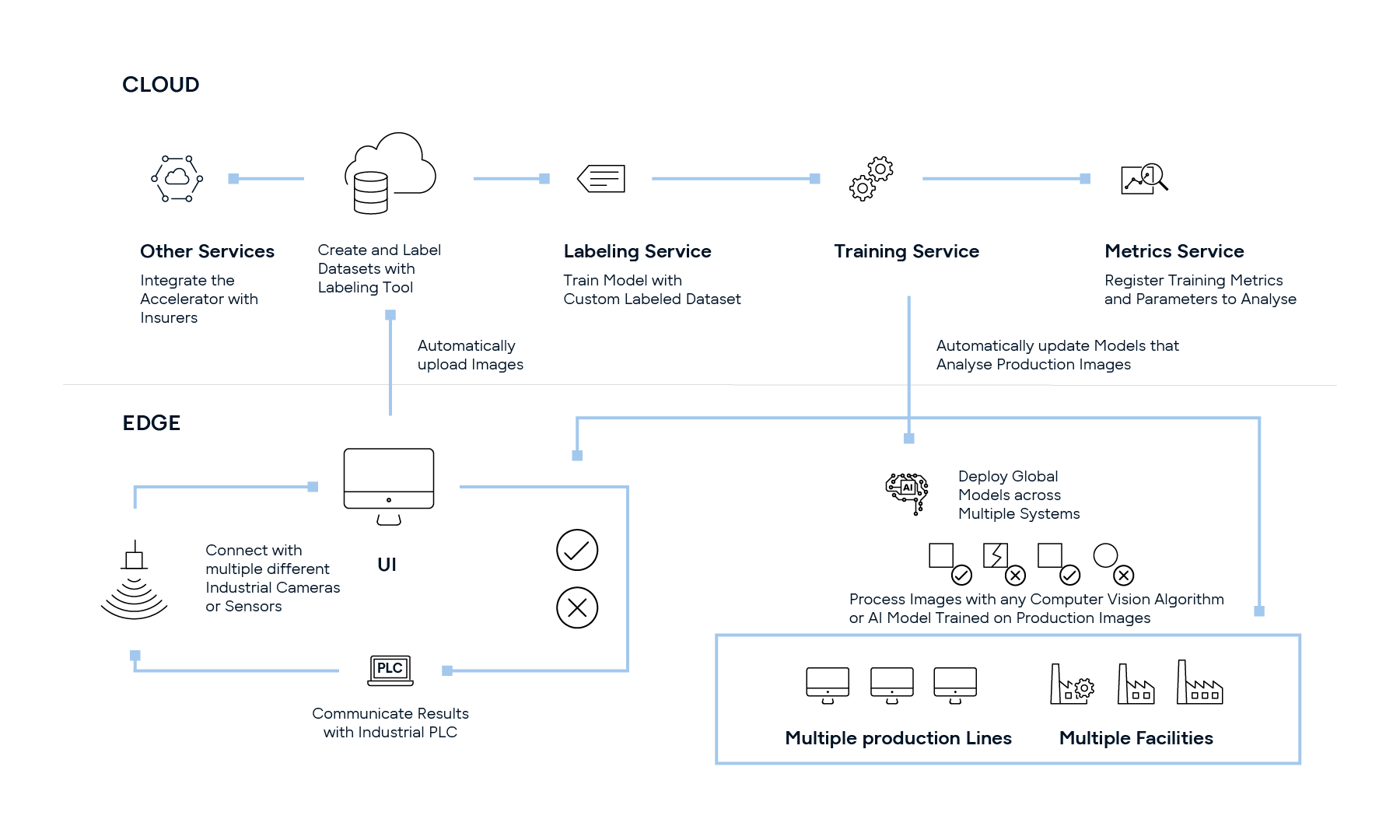

AI-powered Visual Inspection is transforming how businesses ensure quality across industries – from manufacturing and automotive to food, packaging, and logistics. By combining computer vision and machine learning, it ensures near-zero defects, less waste, and smarter operations that scale consistently across sites.

See Precision in Action

Watch how AI inspection transforms production in action.

From Bottles to Welds to Cakes — Precision at Speed

Hot-End Bottle Inspection

A leading glass manufacturer improved hot-end quality control with AI-powered visual inspection. Within milliseconds, the system detects bottle defects in real time, ensuring only flawless products proceed. This automation reduces waste, eliminates manual errors, and increases efficiency, transforming quality control into a seamless, high-speed process.

Package Labelling Inspection

A food manufacturer implemented AI-driven label verification to ensure packaging accuracy. The system reads label contents and compares them to expected values in real time, detecting errors instantly. This automation prevents mislabeling, reduces recalls, and ensures compliance with industry regulations.

Weld Seam Inspection

An automotive supplier implemented AI-driven weld seam measurement to analyse results in real time. The system reduces inspection time from minutes to seconds, ensuring precise seam quality while increasing production speed and efficiency.

Cake Filling Inspection

A food manufacturer implemented AI-driven thermal imaging to predict the amount of cream inside cakes. This real-time analysis ensures consistent filling levels, reduces waste, and improves product quality without disrupting production.